20 Sep Industry 4.0 communication

Industry 4.0, or Fourth Industrial Revolution, is the concept of interconnectivity and communication between industrial equipment and devices. Connectivity between heavy machinery and control devices such as PCs is increasingly needed, so as to transfer and analyze operative data. Communication is needed also for process automation, which enhances operational efficiency in a manufacturing plant. There are many ways to innovate and aim to a smart factory for Industry 4.0, and communication between devices is key to every one of them. Industrial equipment does not usually need fast data transfer, but instead it focuses on consistency and reliability using robust serial communication protocols. RS485 is a prime example of that.

Incentives and subsidies

Many countries have set up Industry 4.0 subsidies to help companies grow and install communication technologies, which can also help combat the economic recession. Custom PCBs and converters can be paid partially or completely with tax rebates. This might include design expenses for custom hardware and firmware, but also products direct costs, depending on your country specific incentives. Next Generation EU, for example, grants funds to innovate european manufacturing companies and help their organic growth. Also extra-EU countries may benefit from institutional funds, like United Kingdom, Indonesia, Australia, United States, and many others.

Institutional funds might be a good opportunity to pay off earlier investments towards innovation. Research and innovation are often the driving forces behind the market competitiveness of a successful company. Structual investments like this are precious, since they just boost the present equipment, instead of buying expensive new instruments. There are several benefits implementing communication in an industrial environment, even without Industry 4.0 subsidies.

Benefits

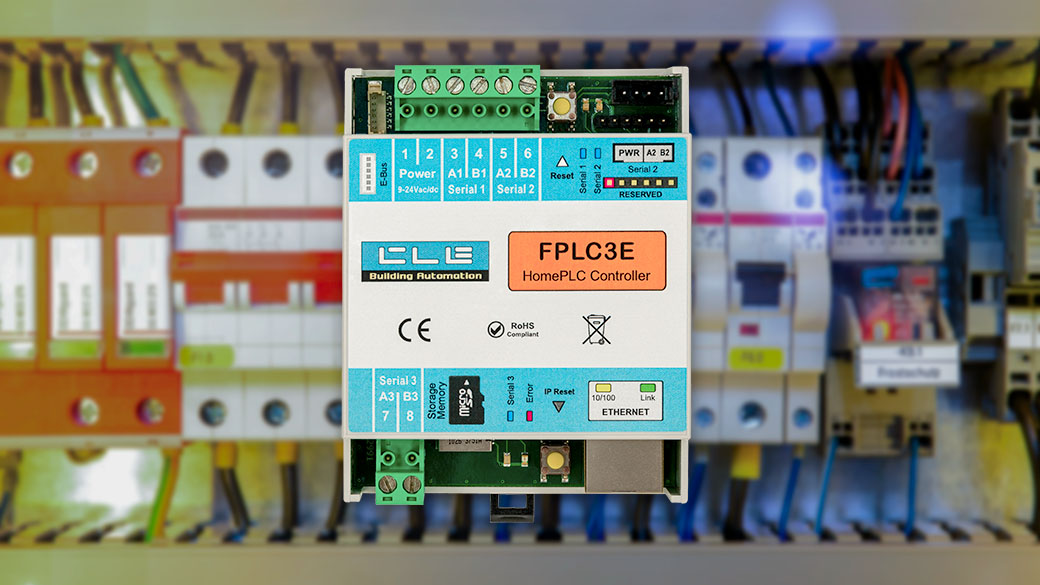

Benefits vastly depend on the factory scenario and application,however digital transformation aims to achieve some key points. Data gathering is an increasingly common trend, since it can be extremely useful in a factory. It might help detect fault patterns in order to predict servicing and maintenance operations, therefore minimizing downtime. Sensor monitoring is usually complementary to data gathering, since it allows even the live monitoring of vital parameters of industrial equipment. Data gathering can also be a powerful tool to automate inspections in case of sudden changes in production efficiency, for example. All these features require a communication between the target machine and a smart device, which can be a computer or a rugged PLC, more suitable for industrial settings.

A powerful device is a great way to centralize the management of different machines, for telemetry acquisition and load balancing, for instance. The use of programmable devices like PCs and PLCs can be cheap to implement, and highly customizable. That’s because you can add management and communication devices on top of your existing (and likely expensive) industrial equipment. Machine to Machine (M2M) communication can be a different way to achieve Industry 4.0 goals, but it usually requires machines to natively have these features.

Equipment management and monitoring is usually adopted also to reduce energy consumption, by knowing exactly when the machines are actually in use. Energy savings play a major role in modern factories, for two main reasons: reducing the carbon footprint and dealing with energy increased cost.

A PLC is a robust and reliable solution for industrial machinery management and control

Related technologies

Many technologies can enable the transition towards a digital revolution, for example automation and robotics, big data analysis, communication and networking. These technologies are deeply interconnected, since their usefulness is greatly enhanced by the other ones. Automating operations can highly increase the efficiency of industrial processes, thus being the core of Industry 4.0. To know when and how to act on a specific process, it’s important to analyze it by means of as many data as possible. Big data and machine learning techniques are the most suitable for this task, and can help predict possible faults and so on. Internet of Things (IoT) is an innovative concept enabled by the aforementioned technologies, and it describes the connection methods and data exchange of a group of devices connected to a network.

The connection can take place via WiFi or Ethernet, but also by means of a serial bus, like a robust RS485 bus or a RS422 connection.

Solutions

RS485 is a serial communication standard, widely used in industry and building automation, for its high noise tolerance and effectiveness over long distances. However, industrial machines don’t always communicate natively with a RS485 bus, so a serial converter is needed. Machines, especially old ones, communicate via another serial standard, namely RS232, which is slower, has limited noise immunity and shorter range. It is good practice to avoid obsolescent standard such as RS232 for long distance communication in noisy environments, and use RS485 instead. A good way to achieve that is using DIN rail RS232-RS485 converters such as PRM/1 or PRMP/1, or with DB9 connectors like RMC/9R, which can be attached directly to the machine.

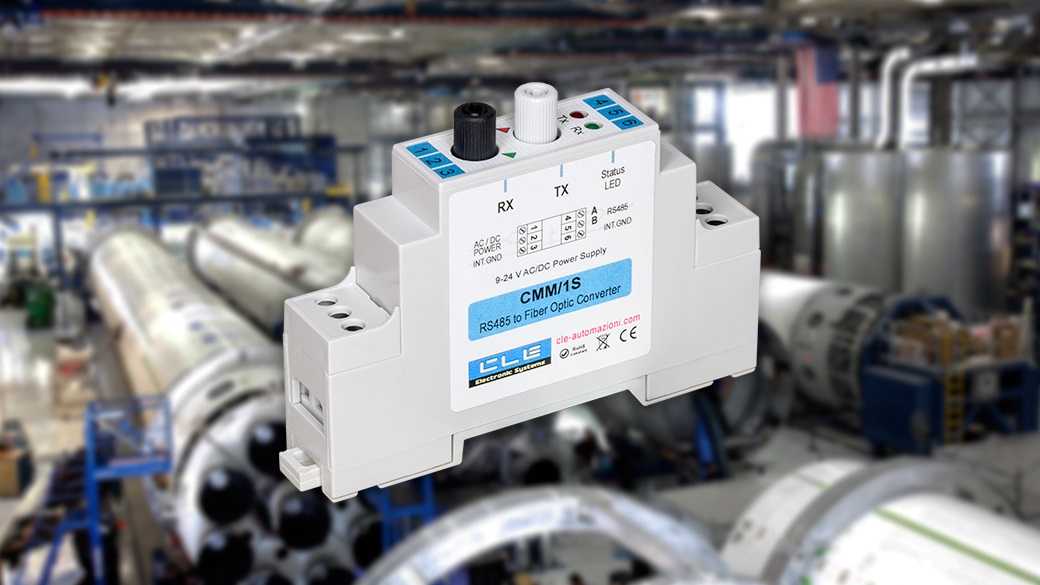

Another advantage of industrial serial converters is the possibility of electrical isolation. It is sometimes needed, but always recommended, to protect devices and machinery against damages caused by voltage surges. To get maximum isolation from voltage surges and electromagnetic noise, optical fiber is the best overall solution. Optical electrical converters such as CRM/1S and CMP/1S are suggested for synthetic optical fiber communication in industrial environments, since they are suitable for DIN rail mounting. IMC/9R and DFP/9S come with a DB9 connector and a smaller form factor, and can be connected directly to the machine or PC.

We can also design custom PCBs for industrial automation and control for Industry 4.0 communication or other specific needs. You can contact us for more information or technical consulting regarding serial converters or industrial communication.